A woodworking shaper is a very handy tool for performing a variety of cutting and carving tasks for craftsmen who wish their work to appear finished and professional.

One of the potential benefits of the shaper is its utility for industrial work.

Lets dive in to discuss the shaper a little more in detail…

Here’s the Answer to What is a Woodworking Shaper

A woodworking shaper is an industrial tool that can be configured in multiple ways to shape wood using common cuts such as rabbeting, edge shaping, end shaping, and shaping curved parts. A shaper generally has more power, speed and flexibility than a router and is suitable for a high volume of cuts.

Table of Contents

How Does a Wood Shaper Machine Work?

One of the primary questions about the woodworking shaper is its utility, and how does it differ from a regular router?

These are both questions that will be explored more in-depth as we progress, however, for many the primary use of the shaper is to add finishing touches to their creation.

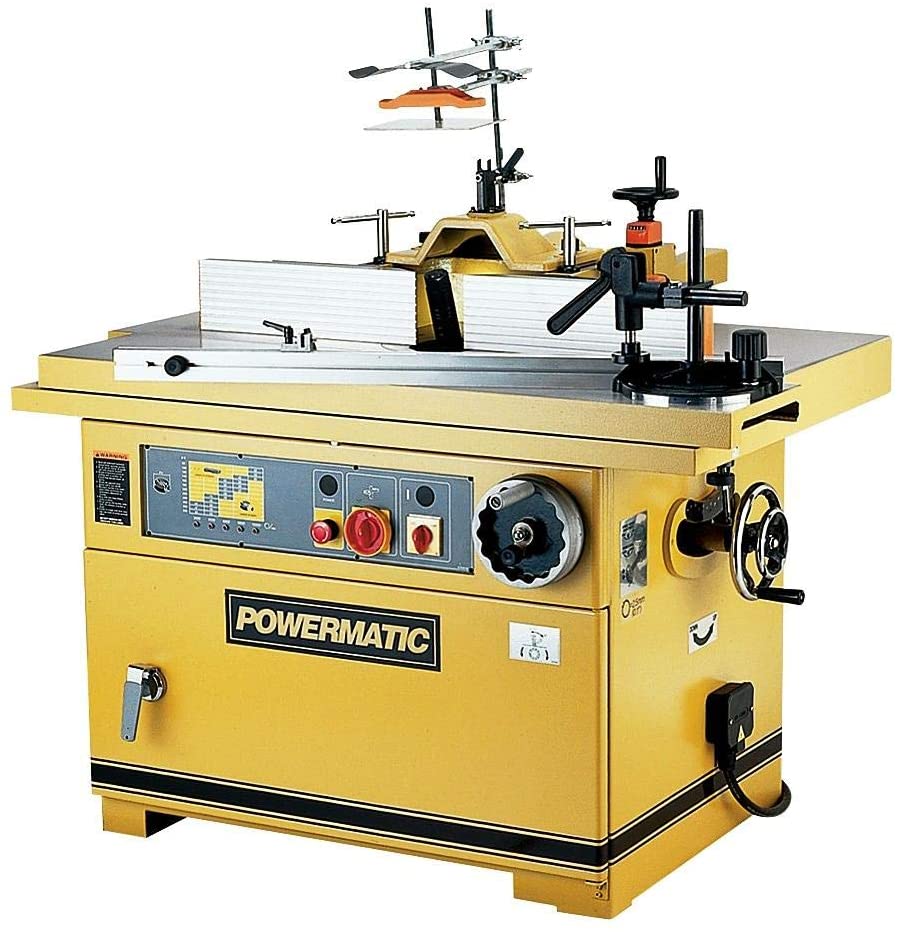

In appearance, the woodworking shaper looks much like a tabletop saw. The blade spins vertically atop a cast iron plate mounted on a bench. The blade is attached to a spindle which is powered by a motor that can regulate the speeds at which the blade spins.

The woodworking shaper works similarly to a router (in fact, this is the most common comparison), with a spindle that propels the cutter. In order to cut the wood, you need to carefully load the wood into the shaper so that it is brought to the blade and cut accordingly.

The wood is held in place by pins along the slide to the blade which enables it to be fed into the blade in a straight line and not go off track.

Likewise, there are fences that are also used to guide the wood straight and in line so as to be cut correctly.

What Can You Do With a Wood Shaper?

The wood shaper utilizes a variety of blades that serve different manner of functions, and enable the woodworker to do much more than simply cut wood. There are smaller blades and slicers for carving the wood for small parts of the woodcraft.

A woodworker can mill wood into smooth, straight boards for making high-quality furniture and household items. The speed of the blade and the size of the blade are some of the most important aspects of the shaper when attempting different projects.

The shaper also expedites tasks of cutting and smoothing wood, which enables craftsmen to not only have finer, smoother, cleaner woodcuts, but also perform cutting, smoothing, and shaping much more swiftly. This, in turn, means it is easier to mass-produce pieces and capitalize.

Here is a cool video on shaper operations.

How Many Types of Woodworking Shaper Machines are There?

There are several varieties of woodworking shapers, but they can generally be boiled down to 10 types.

These are the Gear, Crank, Hydraulic, Horizontal, Draw Cut, Standard, Vertical, Universal, and Contour. Each has a different specialty and is prized for various tasks.

The most commonly used is the Crank Shaper in that it is seen as the most rudimentary, and easily managed. It is powered by a crank attached to the ram which can be utilized to moderate the speeds and directions.

In comparison, the gear shaper is seen as the more complex of the shapers, as it can be moved in a variety of angles due to its gears. It is great for more complex work which requires more attention and management.

What is the Difference Between a Wood Shaper and Router Table?

Essentially, many of the functions of a shaper and a router may seem to be very much the same function. They both cut wood, carve wood, and shape the wood into desired forms for woodworking and crafting.

There are, however, some ways in which they are quite disparate. One of the main ways they differ is in size, speed, noise, and the amount of time in which they may operate at any given time.

To expland a little on each of those points, the size of the router is much more compact and it is more convenient for taking to different places if needed with ease.

Additionally, this obviously makes them more favorable for those craftsmen with small working spaces.

A router is good for precision and small cuts; however, the power behind the shaper is excellent for making large, longer cuts in harder woods for bigger projects.

Lastly, the router tends to perform better in shorter bursts of work, where the shaper can continuously operate for hours at a time. This makes the shaper a good option for industrial usage.

Is a Shaper Better than a Router?

Generally, this depends upon what you plan to do with it. As was stated above, the router is better for those with limited space, or who may need smaller, more precise cuts in wood.

This would imply that the router is a better choice if you are using it for smaller projects, whereas the shaper is ideal for more industrial tasks. Especially for slicing large planks of wood in a straight, clean line.

The cons of a shaper are primarily the cost, the size, and the mess they are known to make when performing cuts. Where a router may cost in the hundreds of dollars, a shaper almost always reaches into the thousands.

Of course, the price may be worth it to you if the projects you plan to do involve the need for a more industrial machine.

Additionally, the size may be a turn-off to some; but this is also one of the assets of a shaper as it can cut much larger sized wood without the need to “take a break”.

All of these factors should be weighed prior to purchase.

Can You Use a Wood Shaper as a Jointer?

The short and sweet answer is, yes the shaper can be utilized as a jointer as well. A jointer’s function is to carve planks of wood to be used for projects such as tabletops and, therefore, the shaper can be modified to suit this purpose as well.

The modifications include adjusting the way in which the fencing is aligned so to cut the wood in a different manner. Many claim the adjustments are not complex, however, there are some shapers that have been specially designed to be modified in order to be utilized as a jointer with ease.

Therefore, if this is something you think you will do often, it might be worth it to get the shapers that have these modifications designed into them.

What are Woodworking Shaper Cutters?

Narrowed down to the basics, a shaper cutter is a blade that cuts the wood. Although there is a great deal more to this part of the shaper.

The cutter tends to be a 3 bladed, disk-like part, which rests on the spindle. Along the sides of the cutter is the fence which holds the wood straight while the cutter slices.

A very informative and helpful video regarding the set-up and use of the cutter can be found below. If you want to see the portion about the cutter, watch from 5:10 – 7:00 however, the whole video is worth the time.

Can a Shaper use Router bits?

One of the best parts about getting a shaper over a router is that the shaper is versatile. The shaper can use router parts, but a router can not use shaper parts.

To some, the extra price paid for a shaper is worth it, because you can easily modify it to be used in similar ways as a router. This means that you can adjust the ways in which you cut and carve to be more analogous to a router’s cut.

So, if you wish, you can modify your shaper to meet different needs for different tasks and it might be worth the extra investment. Especially if you have consistent need for both types of machines.

Do You Need a Wood Shaper for Woodworking?

No, you do not need a woodworking shaper in order to woodwork. That being said, there are many perks to having a shaper for a variety of larger, more intensive projects you may wish to take on.

Somethings to remember about the shaper is that it is a bit of an investment, large, and messy at times.

Although, in spite of these large investments required for the initial purchase and set up, the shaper enables the user to create large projects such as doors or tabletops with much more ease.

What Size Wood Shaper Would You Need?

This depends a lot on the project you are looking to create. The larger the shaper machine, the better it can handle a large volume of work as the motor is not stressed and runs cooler.

For small basic, personal projects a smaller machine rated between 1 HP – 2 HP of power can be used.

If you are looking to do general-purpose shaper work then a shaper rated between 3 HP – 5 HP, is sufficient. For works that involve shaping larger molds, doors, flooring, a 5h HP shaper can generally perform without any issues.

Although, if you want to use your shaper long term for long periods of time for industrial work, machines rated 7 HP and larger are suitable.

What is the Best Wood Shaper?

Some of the most reliable wood shaper brands are Powermatic, JET, Shop Fox, Grizzly, and Laguna.

We had a look at the reviews on Amazon.com and Acmetools.com and on average, customers rate these brands at 4 – 5 stars.

Powermatic and JET offer a 5 year warranty on their wood shapers that are used for personal use. The warranty period is reduced to 2 years if the machines are used for industrial or commercial purposes.

Shop Fox and Laguna offer a 2 year warranty on their machinery whilst Grizzly offers a 1 year limited warranty on their woodworking tools.

Here is a list of the best wood shapers that we put together with its approximate price.

| Name | Price | Link to Store |

| Powermatic Tilt/Slide Shaper 7.5HP 3PH 230/460V | $9,800 | Link |

| Powermatic PM2700 Shaper, 5HP 1PH 230V | $3,800 | Link |

| Laguna Pro Shaper 5 HP 220 V 1 Phase | $3,500 | Link |

| JET JWS-25X Woodworking Shaper, 3HP, 1PH | $2,400 | Link |

| Grizzly G1035 Shaper, 1-1/2 HP | $920 | Link |

Sources